Here is the culprit. A compression truss rod that had glue on the threads from manufacturing where the truss had simply stuck and couldn´t be adjusted anymore. What happens is that the truss breaks instead. How this bass got through QC just amazes me.

Here´s the other end (headstock end) where the threads were contaminated with glue.

Here is the middle stage of neck routing. This is where you can see how exact the neck is made. I made purple heart reinforcements. Neck was too weak.

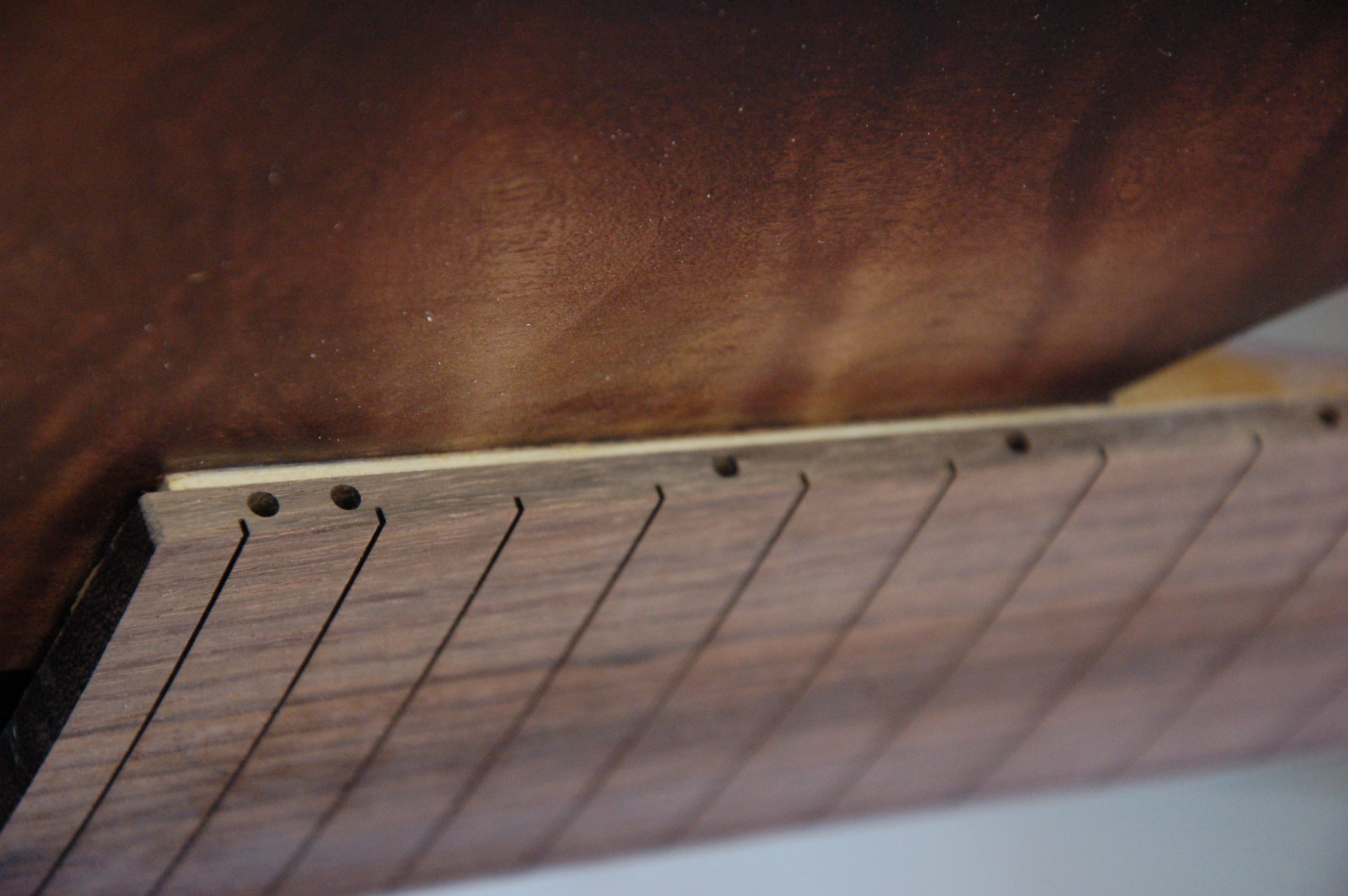

New fretboard on and ready for fine sanding, trimming and fretting.

trimming. Time consuming. As always, you don't want to remove excess in one go.

soon finished.

There, ready for frets.

Fretted with a harder NEO fret.

Bevelling off fret ends, later rounding them with a special file.

Better than original bass. Sounded much more open and clear. It's NOT the pickups making the sound. Lol.

Ebony zero fret nut. The height of the nut is limited to the frets so no removal of the nut is necessary for fret dressing. Clever.

This guy is amazing! I always love it when we get together for discussions about life, basses, food and he is a big Whiskey aficionado! The bass now sports a fantastic response all over the fretboard and has a fantastic low B string undistinguishable from the E string. As it should be. Some would say scrap the bass but there was clearly a potential in it so instead he got a bass that plays and sounds like a €5000 bass and he is very happy with it. The goal is not only to make it look factory but even better than original. And it´s a totally different bass now. For the better. The customer drove 600 km to collect the bass! We had a fun afternoon setting up, good swedish fika and lunch. He couldn´t believe it was the same bass afterwards. This bass could have been used for spares but luckily it went my way instead!